![]() Description of the 2kWth laboratory fluidized bed

Description of the 2kWth laboratory fluidized bed

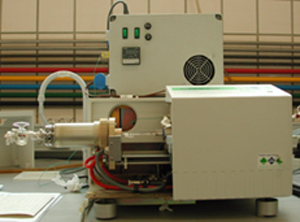

![]() Thermogravimetric analyzer

Thermogravimetric analyzer

![]() Cold model of the FLETGAS system

Cold model of the FLETGAS system

Description of the 2kWth laboratory fluidized bed

Description of the 2kWth laboratory fluidized bed

The reactor is a bubbling fluidized bed 51mm in diameter, with a nominal capacity of 0.7kg/h. The plant is designed for continuous and intermittent tests. It can be fed with mixes of steam, nitrogen and carbon dioxide. It has two ports to extract material from the bed in batch mode. In the ‘freeboard’ there are several ports for the injection of secondary air at three heights.

The reactor has an oven and a preheater both for starting up the plant and for industrial plant simulations. The gas entry flows are adjusted using mass flow rate controllers, as much for the gases which are fed into the lower part of the reactor, as for the secondary air intakes. The continuous feed system consists of a chute, feed screw and long-pitched screw. The system rests on load cells. The upper feed allows for intermittent dosing of granulated materials or pellets. At the end of the downstream there is a gas analyzer which continuously measures CO, CO2, CH4, and H2. All the measurements are recorded on a data acquisition card by means of a PLC. It also has a micro GC Agilens 3000A with two channels which continuously analyzes the gas to measure other gaseous species. The plant is designed to allow gas, tar, contaminating species (nitrogenous and sulphuric compounds and heavy metals), water and particle sampling, both during the continuous and intermittent operation tests. It also has a basic gas purification system composed of a cyclone, impingers with water and biodiesel, filters and adsorber with silica gel.

Thermogravimetric analyzer

Thermogravimetric analyzer

The TGA/SDTA851e/ LF/1600 ºC thermobalance has an oven (maximum sampling size of 900ml) which reaches a maximum temperature of 1600 ºC, and a MT5 scales, with a measurement range of up to 5 g with a 1 μg resolution. This piece of equipment determines the evolution of the weight of a solid sample via a temperature and reactive gas program through time.

Kinetic studies of char gasification from diverse fuels (carbon, olive oil mill residues, meat and bone meal, wastewater plant sludge, etc.) have been conducted using this equipment with carbon dioxide, water vapour and mixes of same.

The results obtained are valuable for the design of systems based on biomass gasification and to understand the phenomena involved in these.

Cold model of the FLETGAS system

Cold model of the FLETGAS system

A cold model of a new gasification system based on a 3-stage fluidized-bed (FLETGAS) has been built with the aim of understanding the fluid dynamics of the system, i.e. the movement of the gas and the char in the beds and the capacity of the loop seal.

The cold model was designed downscaling a hypothetical 2 MWe gasification plant operating on dry sludge, in accordance with the similarity laws for fluid-dynamics.

From the data obtained a fluid-dynamic model was developed to predict the movement of the gas and the solids and also the distribution of the solids between the bed and the seal.

More information about the FLETGAS system can be found here.

Below there is a video which shows the fluidization performance of the cold rig.