Research projects

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

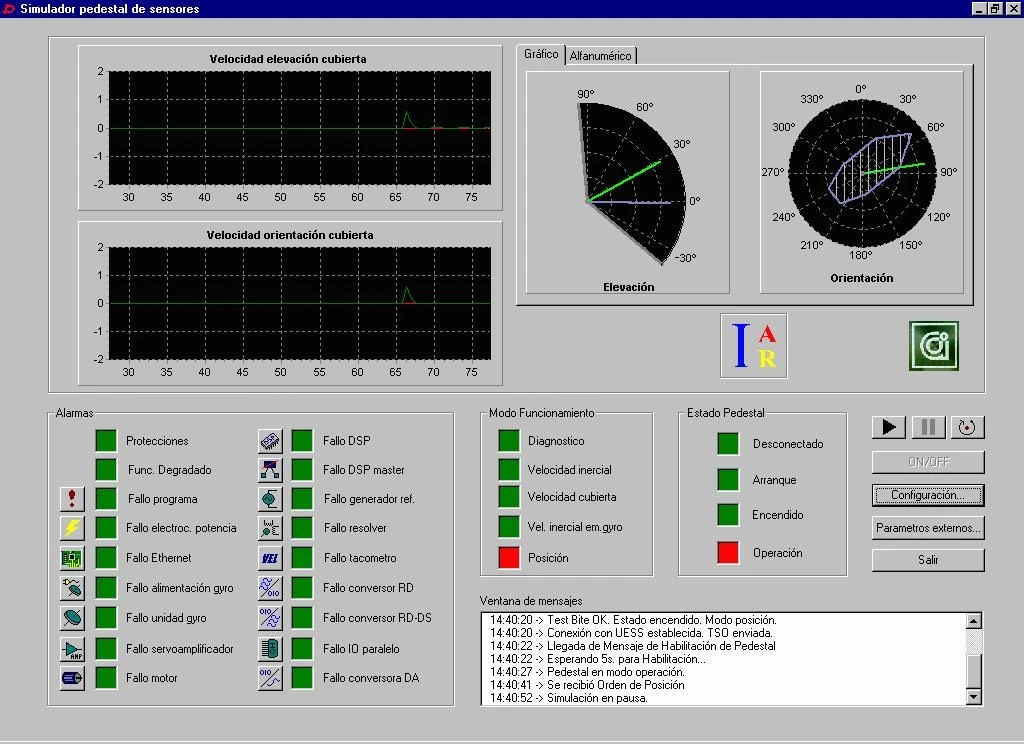

This project aims to study the control problem of gyro-stabilized platforms, and provide concrete solutions for its implementation. The work team is made up of specialists in automatic control, mathematicians and specialists in mechanics. The former are in charge of proposing the control laws that will be applied, while the latter analyze the corresponding behaviors and the third parties advise on aspects of their specialty.

Platform control is a complex problem, especially due to the presence of friction and backlash effects in the gears that make it extremely difficult to achieve high levels of precision in platform positioning.

To solve the problem, the most modern techniques available are applied (Hamiltonian systems, LuGre model for friction, clearance models, etc.).

These techniques will be tested on a pedestal manufactured by the FABA company (see photo), to which gyroscopes and a mobile base will be incorporated to produce disturbances.

This project is a continuation of previous work carried out by the research teams integrated into the project, in collaboration with the company that acts as EPO for the project.

This project aims to provide concrete solutions to control robots. To do this, robust control techniques will be applied to the direct control of the different joints.

The results are being applied to the control of an industrial robot (RM10), and will be compared with the conventional control currently available. This with the aim of developing high-performance, faster and more precise robots in different work situations.

Controllers based on the robot dynamic feedback linearization technique are being developed, as well as others based on global non-linear control. The uncertainties will be taken into account in the robust linear controller located in the outer loop.

Work is being done on the development of controllers based on the LTR, H_2 and H_\infty methodologies, as well as on combined LTR-H_\infty approaches.

In all developments, the effects produced by non-linearities will be taken into account, bearing in mind the multivariable nature of the robot system in question.

For the execution of this project, the industrial controller of the RM10 robot (see photo) has been replaced by a system based on a dSpace firm card from where all the parts of the controller are being made.

The two-phase pomace or «alpeorujo» that is generated in current oil mills and which must be processed in pomace oil extractors presents very different drying problems than the traditional three-phase pomace. This has caused serious operational problems (blockages, fires, low thermal efficiency) and is forcing extractors to modify their drying systems on the fly. The high degree of humidity of the two-phase pomace (>65%) determines that the energy optimization of the drying process is a key aspect of it.

In this context, the two main objectives of the project are the identification of design and operation standards for rotary dryers for two-phase pomace and the development of an automatic system that optimally controls the drying process. The application of the project is guaranteed, since it responds to a real and urgent need of this industrial sector of great importance in Andalusia.

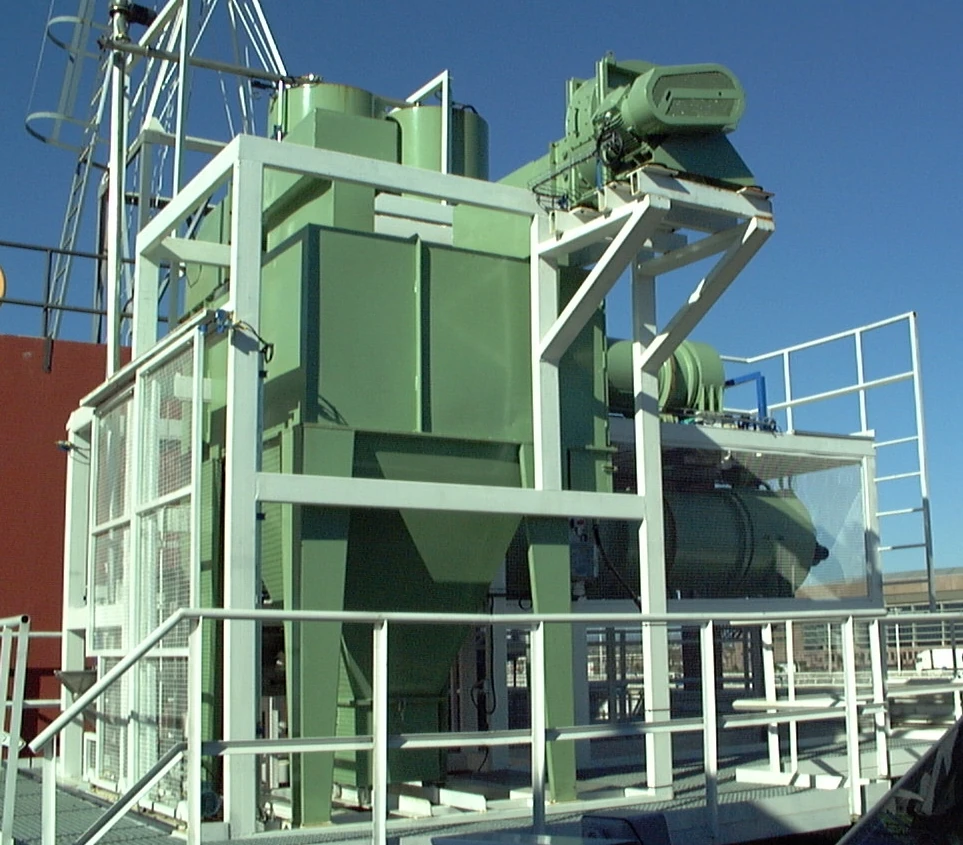

In our laboratories at the Escuela Superior de Ingenieros we have a drying facility (see photo), with a distributed control system that allows comprehensive control and monitoring of the dryer.

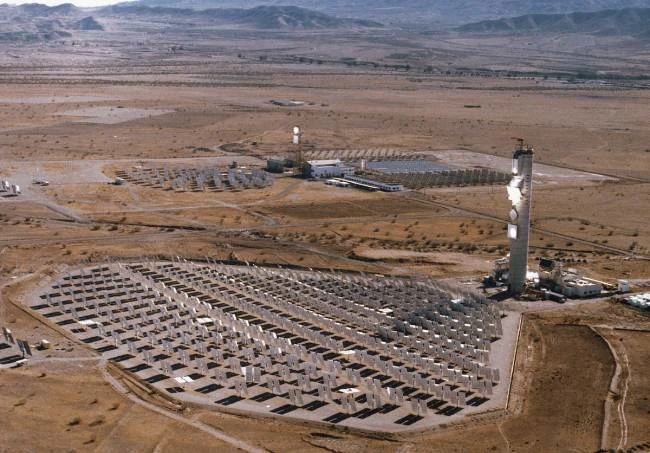

The objective to be achieved in this project is to facilitate the market penetration of central receiver solar thermal systems. This general objective is structured into the following specific objectives:

- Significantly improve the overall profitability of central receiver solar thermal systems, by reducing the cost of their components, especially those that have a greater weight in the total cost of the plant (heliostat field, receiver), and simplifying the O+M associated.

- Improve both the integration of central receiver systems in hybrid plants, through the development of advanced components that allow more efficient integration schemes to be addressed, as well as their suitability for use in high-performance pure solar plants.

- Facilitate the development and consolidation of an industry of its own, through the transfer of technology, the preparation of appropriate market studies and the definition of actions aimed at eliminating non-technological barriers that hinder the penetration of this technology.

In relation to the heliostat, the objective to be achieved in this project is the development of heliostats with its own technology and moderate cost, with a significant reduction (around 40% of the cost per m2), a light and modular structure that is easy to transport, with integrated control system that could support a wireless communication system, and with easy installation and edging. The project includes the design, construction and testing of various prototypes at the facilities of the Plataforma Solar de Almería.

Regarding the receiver, the development of an advanced volumetric receiver is sought, as an essential element of centralization and radiative/convective transfer of the energy captured by the heliostat field. This development is structured according to the following criteria: High-flow receiver (2 MW/m2), with a more compact design, operating at higher temperatures (1,000 ºC), with a ceramic matrix, regulation system that will automatically adjust the air recirculation values and local incident solar radiation flux values, and also with a modular cold air return system optimized for the specifics of the new high-flow receiver design, and integrated into the thermodynamic cycle to be used. The project contemplates the development of a prototype with a power of around 500 kWt that would be tested in the existing test-bed at the Plataforma Solar de Almería.

The project is completed with a conceptual design of a typical plant and a technical and economic feasibility analysis, as well as a technology commercialization study. The project is formed as an Integrated Project with the participation of two Research Centers (IAER and CIEMAT-PSA), a company (INABENSA) and the University of Seville, all of them through centers located in the Autonomous Community of Andalusia.

The objective of this project is to design and implement a controller for the stabilization of a pedestal on the deck of a ship, as well as the integration of the complete system within a monitoring subsystem. Robust, non-linear control techniques are being applied to control the two pedestal motors. Simulators for the mechanical part and the closed-loop system are also being carried out to be integrated into a local network of simulators for ground tests.

One of the clearest applications of solar energy is for the production of cold for the obvious reason that when cold is most needed is when there is more incident solar radiation and, therefore, it is hotter.

In Andalusia this situation is very evident and for this reason there are university groups that have been interested in this matter for some time. Specifically, one of the procedures to achieve the desired cold from solar energy is through absorption machines that, as is known, produce cold by consuming heat in their generator. This heat can be provided in many different ways and one of them is from solar radiation in its thermal option.

Previous studies led to knowledge of the situation and the great potential of these systems became clear. There was also knowledge of the favorable repercussions for the environment of using this cold system since the solar (or residual) energy used to produce cold is less conventional energy that must be produced with the consequent savings in environmental impact. .

The Andalusian Institutes of Automation and Robotics and Renewable Energies obtained funds for the acquisition and assembly, on the roof of the Workshops and Laboratories buildings of the Higher School of Engineers, of a complete installation of cold production by absorption with solar energy and supported by a natural gas boiler. The installation has been designed and built in such a way that it allows the testing of the supply and consumption subsystems jointly and separately in a context of automation and control, which is what can allow the optimization of the whole.

The objective of this project is to design and implement a controller for a pedestal that will act as a sun tracker. Said pedestal will carry high-concentration solar panels that need greater accuracy in tracking the sun than conventional photovoltaic panels. For this, the problem will be addressed by developing a precision solar tracking strategy adjusted to the angular opening of the system and its subsequent implementation on the real system. In addition, energy saving considerations must be taken into account. The developed strategy will be validated by simulation and field tests on a monitoring pedestal available in the laboratories of the Institute of Automation and Robotics. This project is financed by the company INSPIRA.

The purpose of this work is the realization of an automatic sealing system for section 18 of the A320 nacelle, using an ASEA IRB-2000 six-degree-of-freedom manipulator robot from the company EADS. This operation is carried out once the nacelle assembly has been completed, and consists of applying a paste-like sealant to the joints between the different components of the nacelle structure (stringers, clips and frames) to protect said joints against to corrosion. The function of the sealant is to prevent the entry of liquids into these joints. The idea is to have a supervision station from where, in a comfortable way, the gondola is defined with the help of a program. In this way, the system will store all the positions and sealing tasks of the basket and later the robot will carry out the operation in real time. For the operator, no operation will have to be carried out on the robot, since it will receive the orders directly from said supervision station. This project is financed by the company EADS-CASA.

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón

Contenido del acordeón